Block for 32 Remote Control Modernized "BRC-32M"

1. Purpose and composition of the BRC-32M unit.

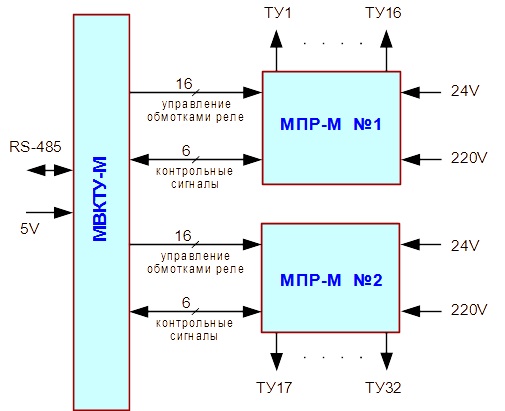

The modernized BRC-M Block for Remote Control Modernized is designed to issue telecontrol commands via one of 32 channels.

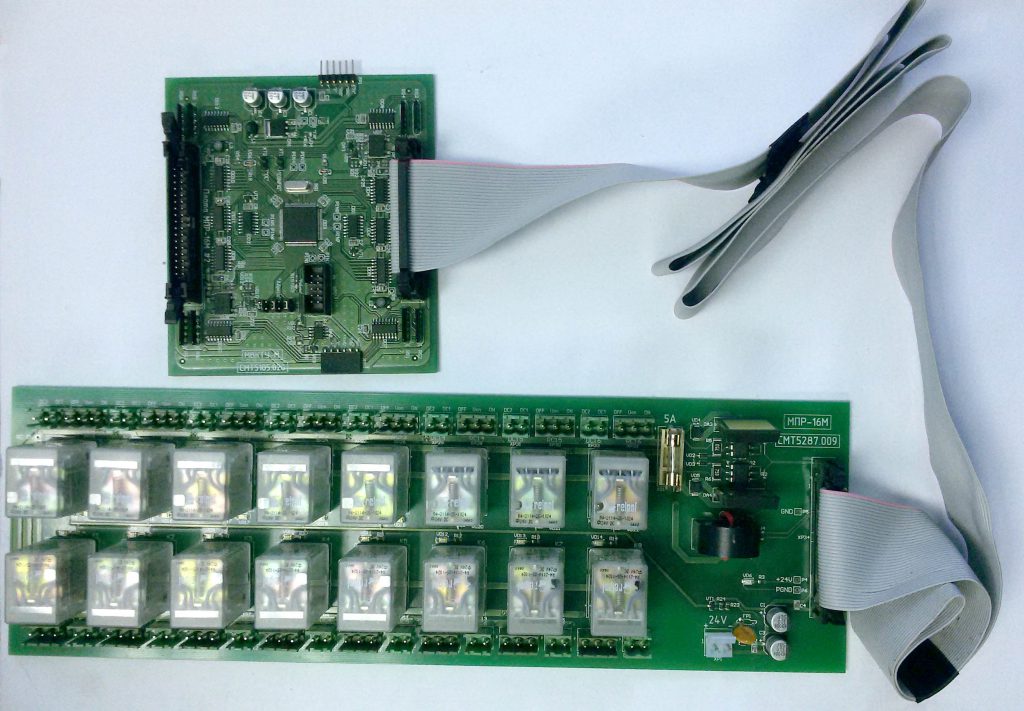

The block includes:

— modernized module for issuing telecontrol commands MVKTU-M — 1 piece;

— upgraded intermediate relay module MPR-M — 2 pcs.

The main application is work as part of the MKSU of KP TM devices at power facilities. Can work in conjunction with a controller

KPL-32 as part of the MKSU cabinet or separately with the ability to control via a communication channel.

2. Purpose of the MVKTU-M module.

The modernized MVKTU-M module for issuing telecontrol commands is designed to control one or two boards

MPR-M and the ability to exchange data via a communication channel (physical interface RS-485) using the Modbus RTU exchange protocol.

The module is based on the ST32F100V8 microcontroller from STMicroelectronics.

The MVKTU-M module performs:

— issuing technical control commands;

— reading the state of control sensors located on the MPR-M board;

— reading the state of the relay windings located on the MPR-M board;

— exchange via communication channel;

— analysis of the performance of the BRC-M unit, and display of the unit’s status via the communication channel.

2.1 Characteristics of the MVKTU-M module.

— maximum number of control channels — 32 (number of connected MPR-M boards — 2 pieces);

— the ability to set the signal duration for each channel separately in the range from 1s to constant on;

— automatic determination of the type of current: direct, alternating;

— the ability to disable control of power circuits at the stage of performing specifications;

— the ability to operate two MPR-M boards from different sources of operational voltage, both direct and alternating current;

Note. Only one technical command is executed per unit of time. When the next command arrives, before the end

execution of the previous one, it is ignored, and an exception response is sent over the communication channel.

2.2 Characteristics of the communication channel.

The communication channel is a physical interface RS-485, the output driver has no galvanic isolation from the control circuits.

Exchange protocol — Modbus RTU.

Exchange speeds — 1200, 1800, 2400, 4800, 7200, 9600, 14400, 19200, 38400, 56000, 57600..

Parity has 3 meanings:

— without control;

— parity check;

— odd parity check.

The communication channel address can be set in 2 ways:

— using jumpers (values from 1 to 31);

— using service software (values from 1 to 246).

2.3 Electrical characteristics.

MVKTU-M is powered by DC 5 (±10%) V. Power consumption is no more than 0.2 W.

2.4. Performance characteristics.

MVKTU-M is made in the form of a bare board, which is installed in plastic trays with DIN-rail mounting.

The board has a connector with pins on one side for connection to the CONNECT-32M adapter board or to the MPDS32-M board. On the other side of the board there is a female connector. Using this connector, the board can be interfaced with a similar MVKTU-M board or MPDS32-M board.

Operating temperature range from minus 20 to +70 ºС.

The MVKTU-M module can be configured via a communication channel from a PC on which specialized service software is installed.

The board has a connector for recording application software and software updates via the JTAG technological serial channel.

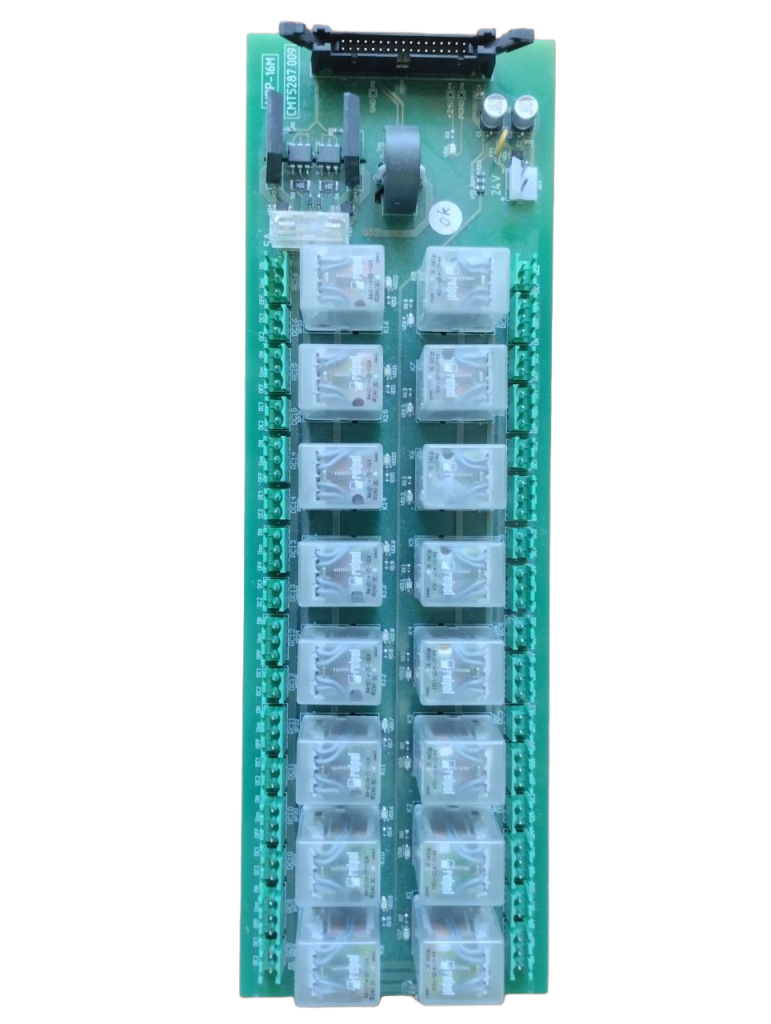

3. Description of the MPR-M intermediate relay module.

3.1. Module characteristics.

— maximum number of control channels—16 discrete power signals (~/= 220V, 5A

or ~/= 110V, 5A);

— outputs — normally open contacts of electromechanical relays;

— type of activation — two-stage: 1st stage — electromechanical relay, 2nd stage — two common power electronic switches — one for turning on the device, the other for turning off the device;

— the ability to output a signal for each channel separately in the range from 1s to 5s with a resolution of 0.1 s;

— the ability to use one of the channels to organize a “Dry Contact” type signal via a separate connector;

— diagnostics of the operation of input relays to the level of contact groups (monitoring the health of the power electronic switch, electromechanical relay windings and “sticking” contacts);

— monitoring the presence of switching voltage and load;

— limits of load resistance at which the operability of diagnostic circuits is guaranteed (with

power voltage value ~/= 110V or ~/= 220V) — 150 kOhm;

— the ability to disable control of power circuits at the software level;

— short circuit protection using fuses and current sensor,

Type of protection — switchable (detects the fact of a short circuit and disables power electronic keys);

— short circuit sensor response threshold — 5A.

3.2 Electrical characteristics

The power supply of the MPR-M power part is carried out from direct or alternating current 220 (±10%) V. Consumption by control circuits at an operating voltage of 220V:

— the maximum current consumed by the control sensors during the execution of specifications is 7 mA.

— there is no consumption of control sensors in power circuits in standby mode.

Power supply of low-voltage control and monitoring circuits of MPR-M is carried out from direct current

24 (±10%) V. Power consumption:

— in standby mode (all relays are disabled) no more than 0.3 W;

— in the mode when all relays are turned on, no more than 17 W.

3.3 Performance characteristics.

The MPR-M module is made in the form of a bare board, which is installed in plastic trays and mounted on a DIN rail.

All external connections are made by wires to plug-in screw connections.

Operating temperature range from minus 20 to +70 ºС.

Made in Ukraine