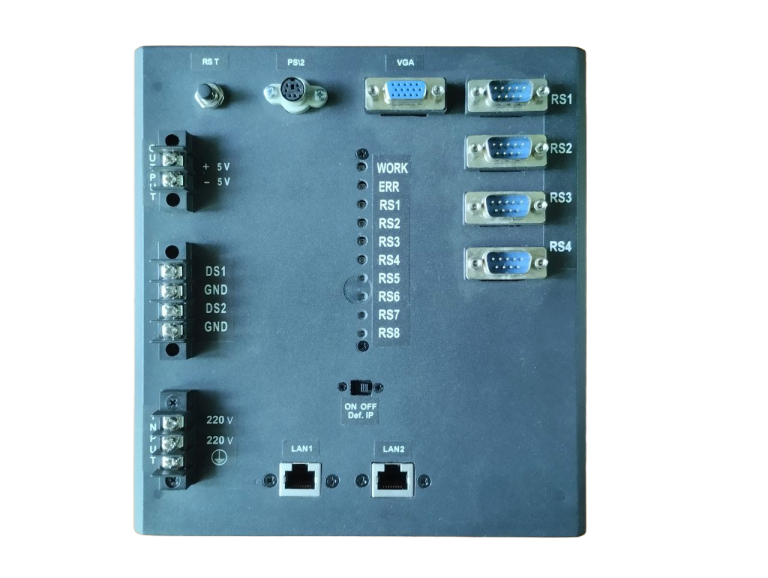

Programmed Logical Controller KPL-32

Telemechanics controller KPL-32

Autonomous component part of the MKSU — KPL-32

Brief technical characteristics of the device for adapting non-standard protocols for teleinformation exchange to one of the protocols of the international standard (KPL-32)

1. Technical characteristics:

— made on the basis of a module from the ICOP family of industrial controllers;

— basic Linux operating system (v. 2.6.29);

— number of dedicated digital channels with RS-232 interface: 4 -channels; 8-channel; 12-channel;

— Ethernet 10/100 Base – 1 or 2 pcs;

— duplex channels with RS-232 interfaces, for data exchange according to standard asynchronous protocols at speeds ranging from 100 to 115,000 baud;

— design execution – plastic case with mounting on a DIN rail;

— overall dimensions 150x70x110 mm, complete with a mounting bar with fasteners for installation on a DIN rail;

— mechanical protection — IP20;

— External connections using:

a) to subordinate devices with synchronous exchange protocols and to 24 V power circuits — terminal disconnectors;

b) to the computer network – RJ-45 connector;

c) 4, 8 or 12 digital dedicated channels with RS-232 interface — DB-9 connector;

— service LEDs are installed on the two side walls of the case, which reflect the presence of secondary power supply voltages and the operating status of both the device itself and data exchange through the communication channels involved.

2. List of performed functions:

− cyclic polling of subordinate devices regarding the data of the vehicle, TI;

— reception of TC, TI data, which are transmitted cyclically without polling;

— cyclic transfer of TK, TI data without requests;

− synchronization of own system clock by the control server;

— reception of TU commands from the control server and their retransmission to the corresponding subordinate device;

— temporary archiving of operational information in case of loss of communication channel with the control server;

— issuing, at the request of the control server, the full volume of information about the collected values of parameters of the vehicle, TI;

− setting of insensitivity zones for TI parameters;

− setting the parameters of TV information exchange channels;

−supports exchange using a number of specialized protocols such as:

- Modbus RTU COM (Master/Slave);

- Modbus RTU TCP/IP (Master/Slave);

- IEC60870-5-101(Master/Slave);

- IEC60870-5-103(Master/Slave);

- IEC60870-5-104(Master/Slave);

- IEC61850-8 MMS (Master/Slave);

- DNP3.0 TCP (Master/Slave);

- DNP3.0 COM (Master/Slave);

In addition, it supports exchange using a number of specialized protocols such as:

- AIST (Master/Slave);

- GRANIT (Master);

- KOMPAS (Master);

- TM120(Master);

- MKT-3 (Master);

- MKT-2 (Master/Slave);

- TM-512 (Master/Slave);

- SPA ABB company (Master)

- GPS time (Master)

- NTP server/client

- SNMP server

- WEB SCADA with TLS

- PLC functions aka IEC 61131

− control of communication parameters with a subordinate device, formation of service logic signals regarding the working status and quality of communication;

− update of configuration parameters and built-in software remotely via a network channel using KPLconfig program;

— service software for configuration under the conditions at the facility.

3. Operating characteristics:

— work in closed premises with a high level of danger;

− ambient temperature from -20 to +50 °C;

− supply voltage +24 V direct current, power consumption up to 8 W;

— warranty period of service 36 months;

— warranty period of 12 years.

Note. KPL-32 is a component of the MKSU product (TU U 31.2-25641912-001: 2011) and can be supplied as a separate device.

Made in Ukraine

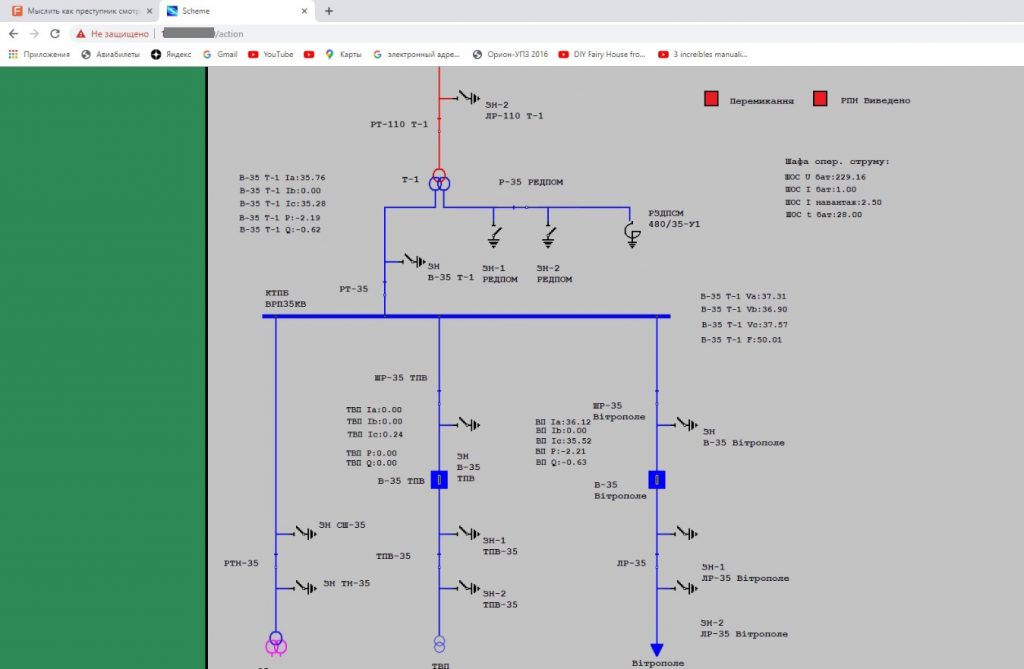

An example of the implementation of the WEB interface of the KPL-32 controller.